In today’s fast-paced world of automotive and electrical systems, reliable connectivity is no longer a luxury—it’s a necessity. Whether you're a seasoned mechanic, a passionate DIY enthusiast, or an electrical engineer working on high-demand projects, the importance of a durable and efficient plug cannot be overstated. That’s where the H4 plug steps in, offering a powerful solution designed for superior performance in even the most challenging conditions.

When Connectivity Meets Reliability: Meet the H4 Plug Built to Last

Modern vehicles and electrical systems rely heavily on seamless connectivity to function efficiently. However, traditional plugs often fall short when exposed to extreme temperatures, moisture, or heavy current loads. These conditions can lead to intermittent connections, performance degradation, and even complete system failure. The H4 plug, however, is engineered to overcome these challenges with a design that prioritizes stability, durability, and high conductivity. Built to endure, it ensures your systems remain powered and performing at their best.

Why Your Electrical System Deserves Better Than Standard Plugs

Many off-the-shelf plugs may seem adequate at first glance but often fail under real-world conditions. Poor contact, corrosion, and unstable current flow can all compromise the integrity of your electrical setup. These issues not only affect performance but also shorten the lifespan of connected devices. Choosing a high-quality H4 plug means investing in peace of mind. Its superior materials and thoughtful engineering ensure long-term reliability, protecting your equipment from the inside out.

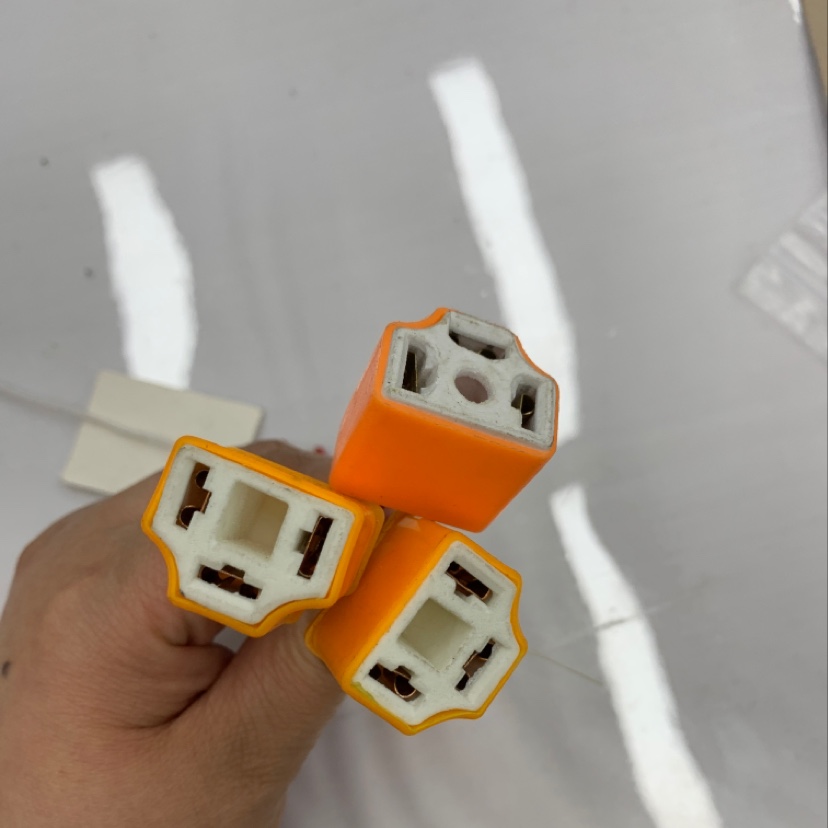

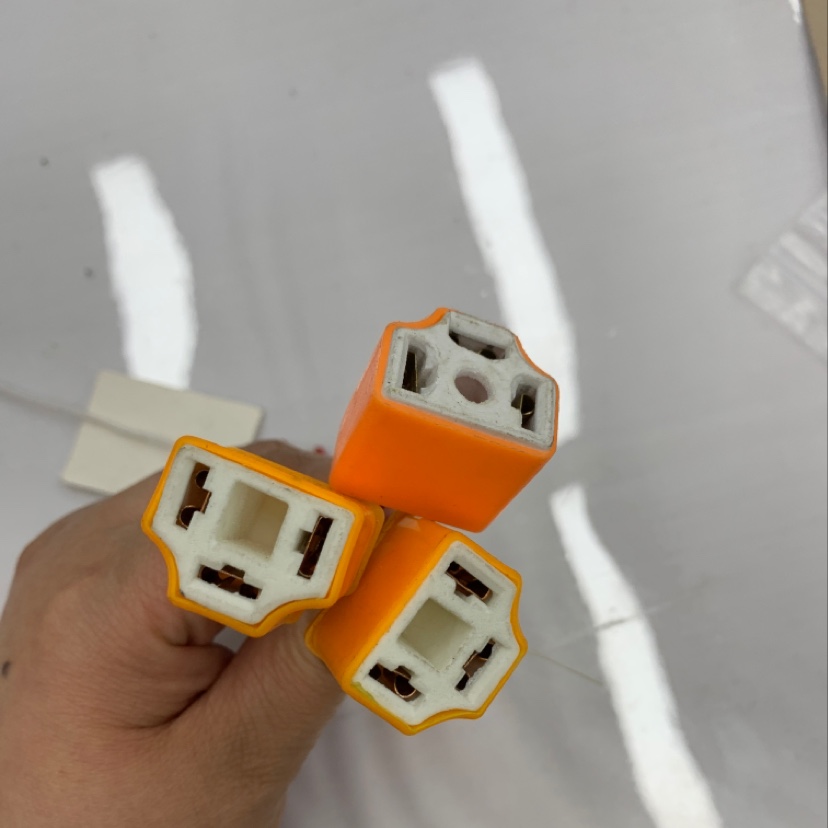

Under the Hood: Inside the Engineering of a Premium H4 Plug

The true strength of the H4 plug lies in its construction. At its core are high-conductivity copper contacts that minimize resistance and maximize current flow. The outer shell is crafted from heat-resistant, durable thermoplastic that shields against environmental stressors such as moisture, dust, and vibration. The plug also features a secure locking mechanism that prevents accidental disconnections, making it ideal for use in dynamic environments. Whether under the hood of a vehicle or in an industrial lighting system, the H4 plug maintains consistent, uninterrupted connectivity.

From Garage to Grid: Real-World Applications That Demand Precision

The versatility of the H4 plug makes it a go-to choice across a wide range of applications. Car enthusiasts rely on it for stable headlight and fog light connections, while professional repair shops integrate it into complex electrical diagnostics. In construction and heavy machinery, it powers auxiliary lighting systems that must withstand rough handling and outdoor exposure. Even in outdoor lighting and portable power solutions, the H4 plug delivers consistent performance where reliability is critical. Users consistently report fewer failures, easier maintenance, and a noticeable improvement in system efficiency after switching to this advanced plug.

The Difference You Can Feel: How Our H4 Plug Stands Out

While many H4 plugs exist in the market, not all are created equal. What sets our H4 plug apart is the attention to detail—from the high-grade copper contacts that ensure minimal voltage drop to the weatherproof housing that resists UV degradation and corrosion. It’s designed for quick installation, fitting seamlessly into existing setups without the need for modifications. Customers have noted a significant reduction in electrical issues after upgrading, with many citing the plug’s ease of use and long-term value as key factors in their decision to switch.

Plug into the Future: Why Choosing the Right H4 Matters for Long-Term Performance

Choosing the right H4 plug isn’t just about immediate functionality—it’s about safeguarding your system’s future. Inferior plugs can lead to costly repairs, safety hazards, and downtime. By investing in a premium H4 plug, you’re not only enhancing current performance but also extending the life of your equipment. It’s a small component that makes a big difference, ensuring your systems operate smoothly, safely, and efficiently for years to come.

Behind the Build: What Goes Into Crafting a High-Performance H4 Plug

Every H4 plug we deliver is the result of meticulous engineering and rigorous quality control. From the selection of raw materials to the final performance tests, each step is designed to meet and exceed industry standards such as ISO and CE. Our manufacturing process includes precision molding, contact plating, and durability testing under simulated real-world conditions. This commitment to excellence ensures that every plug meets the demands of professional use while offering consumers a product they can trust without compromise.