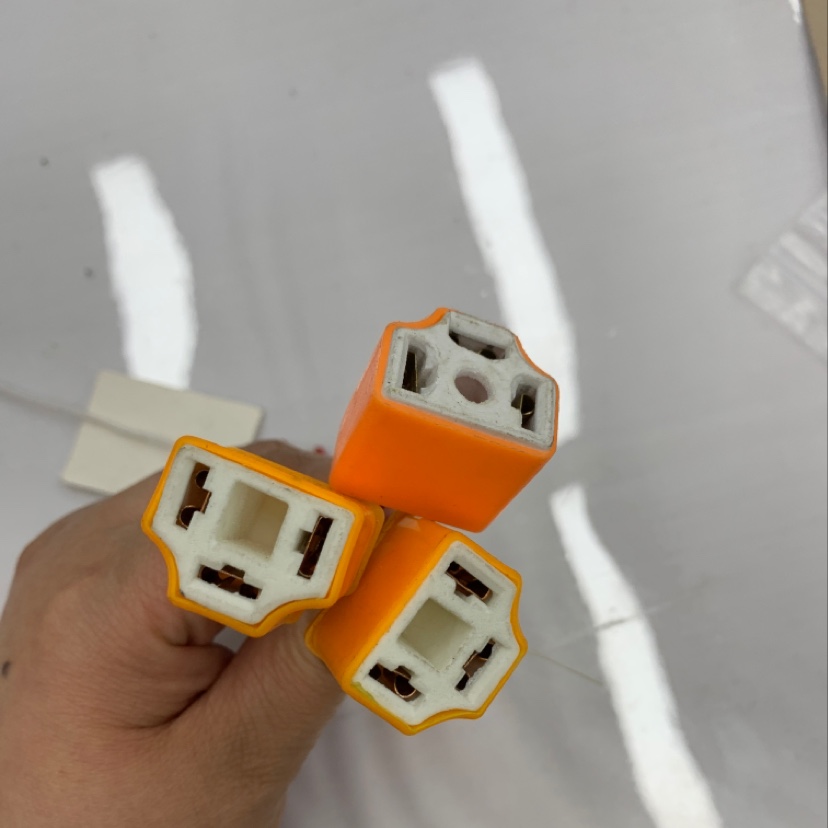

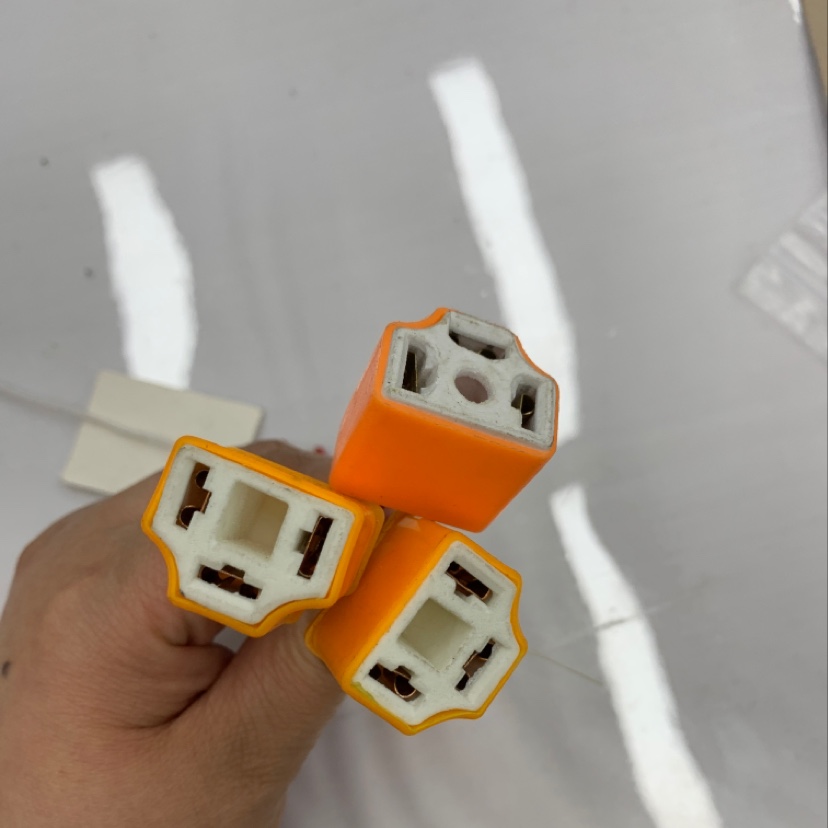

The H4 Plug Unveiled: What Makes It Unique?

At first glance, the H4 plug may appear similar to other connectors, but its design and functionality set it apart. This four-pin configuration is widely used across a variety of industries due to its balanced power delivery and secure connection. Unlike the H3 or H5 variants, the H4 offers a unique combination of current-handling capacity and compact size, making it ideal for applications where space is limited but performance cannot be compromised.

The H4 plug’s physical design features four distinct contact points arranged in a square pattern. This configuration allows for stable and even distribution of electrical current, minimizing the risk of overheating or power loss. Its robust plastic housing and corrosion-resistant metal contacts ensure long-term reliability, even in demanding environments.

Why the H4 Plug Stands Out in Performance

One of the most compelling reasons users opt for the H4 plug is its superior performance under pressure. Whether it's powering high-wattage devices or enduring extreme temperatures, this connector delivers consistent and safe energy transfer. The H4’s ability to handle higher currents without voltage drop makes it a go-to choice for automotive lighting, industrial tools, and outdoor equipment.

In environments where heat buildup is a concern, the H4 plug shines. Its materials are engineered to resist thermal degradation, which helps maintain structural integrity and conductivity over time. Additionally, built-in safety features such as short-circuit protection and overload resistance provide peace of mind, especially in critical applications like automotive systems or manufacturing equipment.

Choosing the Right H4 Plug: Key Considerations

When selecting an H4 plug, several factors come into play beyond just price. The material of the contacts—often copper or aluminum—can significantly affect conductivity and durability. Copper offers superior electrical performance and longevity, while aluminum is lighter and often more cost-effective.

Compatibility is another crucial factor. Before purchasing, ensure your device or wiring system supports the H4 standard. Many modern electronics and automotive components are designed with H4 compatibility in mind, but it's always wise to double-check specifications.

Not all brands are created equal. Look for manufacturers with a track record of quality and certifications such as CE, RoHS, or UL. These marks indicate that the product meets international safety and environmental standards. Balancing cost and performance is key—opting for a cheaper, lower-quality plug may lead to frequent replacements and potential system failures.

Installation Made Simple: How to Set Up Your H4 Plug

Installing an H4 plug doesn’t require advanced technical skills, but it does demand attention to detail. Begin by gathering the necessary tools: wire stripper, screwdriver, crimping tool, and heat-shrink tubing. These items will help ensure a secure and long-lasting connection.

Start by stripping the insulation from the wires, taking care not to damage the conductors. Insert each wire into the corresponding terminal on the H4 plug and tighten the screws securely. For added protection, apply heat-shrink tubing over the exposed wires to prevent short circuits. Once everything is connected, perform a continuity test to confirm the plug is functioning properly.

Common mistakes during installation include loose connections, incorrect wire placement, and neglecting to insulate exposed terminals. Avoiding these pitfalls will ensure your H4 plug performs reliably for years to come.

Maintenance Tips to Keep Your H4 Plug in Top Condition

Regular maintenance can significantly extend the life of your H4 plug. Dust and debris can accumulate over time, leading to poor conductivity and potential overheating. Use a soft brush or compressed air to clean the plug periodically, especially if it's used in dusty or outdoor environments.

Check the tightness of the wire connections every few months to prevent loosening due to vibration or thermal expansion. If you notice any signs of corrosion or discoloration on the contacts, it may be time to replace the plug. Keeping the plug dry and storing it in a cool, dry place when not in use will also help maintain its performance.

Real-World Applications: Where the H4 Plug Excels

From the automotive industry to DIY electronics, the H4 plug proves its versatility across a wide range of applications. In car lighting systems, for example, the H4 is the standard for headlights, offering both high beam and low beam functions in a single unit. Its ability to handle high current loads without overheating makes it ideal for this demanding environment.

Industrial machines often rely on the H4 plug for connecting power tools and auxiliary devices. Its robust design ensures uninterrupted operation even in high-vibration settings. Outdoor enthusiasts also appreciate the H4 plug’s durability in portable power systems, such as solar generators and camping lights, where reliability is essential.

For hobbyists and electronics tinkerers, the H4 plug is a popular choice for custom builds and power upgrades. Whether you're modifying a drone or building a custom LED lighting setup, the H4 plug offers the flexibility and performance needed for advanced projects.

What’s Next for the H4 Plug? Future Trends and Innovations

As technology evolves, so too does the H4 plug. With the rise of smart devices and integrated systems, there’s growing interest in enhancing the H4 plug to support data transmission alongside power delivery. This could open new possibilities in fields like IoT, where both energy and communication are critical.

Material science is also playing a role in the H4 plug’s evolution. Lighter, more conductive materials are being explored to improve efficiency and reduce energy loss. Additionally, environmental considerations are pushing manufacturers to develop recyclable and eco-friendly versions of the plug.

While the H4 plug remains a staple in many industries, future standards may eventually introduce new connectors that combine its best features with cutting-edge technology. However, for now, the H4 continues to hold strong as a reliable and widely supported option.

Hearing from Real Users: What People Are Saying

Engineers and technicians often praise the H4 plug for its dependability and ease of integration into complex systems. Many highlight its consistent performance under high load and its ability to withstand harsh conditions without failure. For DIY enthusiasts, the plug’s accessibility and straightforward installation process are major selling points.

Everyday users appreciate the H4 plug’s durability and long-term value. Online forums and tech communities frequently discuss best practices for installation and maintenance, with many users sharing tips on how to maximize the plug’s lifespan. Overall, the consensus is clear: the H4 plug offers a compelling mix of performance, reliability, and versatility.