It starts with a flicker. You're driving home late at night, the road ahead lit only by your headlights, when suddenly—your beam stutters. One second you can see clearly; the next, darkness creeps in from the edges. You tap the dashboard, wiggle the switch, and just as quickly, the light returns. This common frustration often isn’t due to a failing bulb or weak battery—it’s a silent culprit hiding in plain sight: the humble H4 plug.

When Current Meets Precision: The Story Behind the Flickering Light

That erratic glow isn’t random—it’s a symptom of poor electrical contact. In many halogen headlight systems, the H4 plug serves as the critical bridge between power source and illumination. When corrosion sets in or vibrations loosen its grip over time, the connection degrades. Voltage drops. Performance wavers. And safety diminishes. The H4 plug doesn't just carry electricity—it ensures it flows steadily, reliably, and without interference.

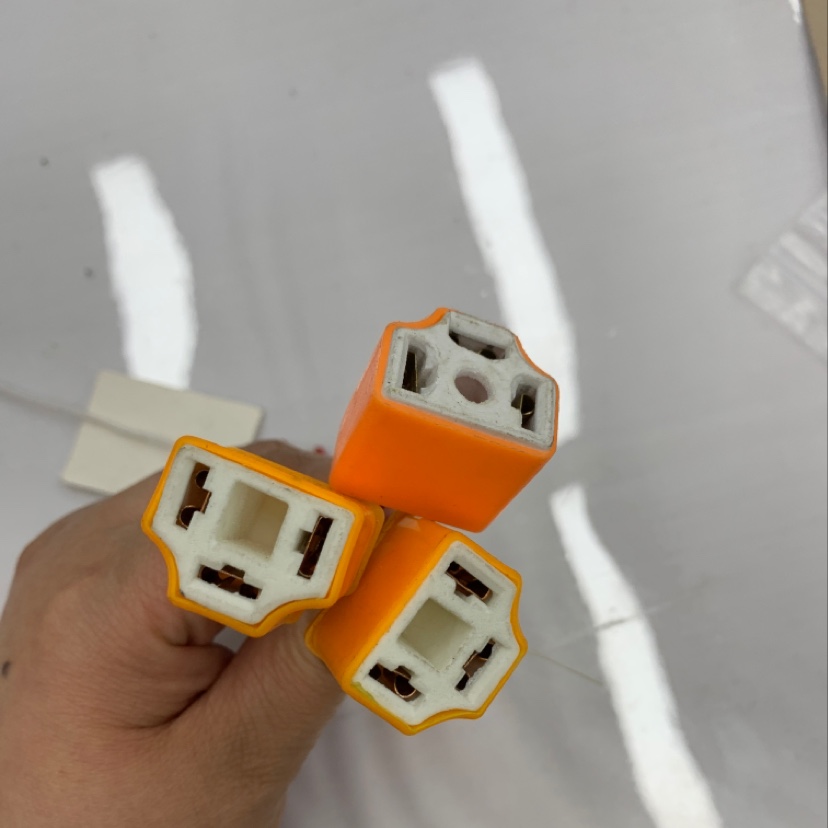

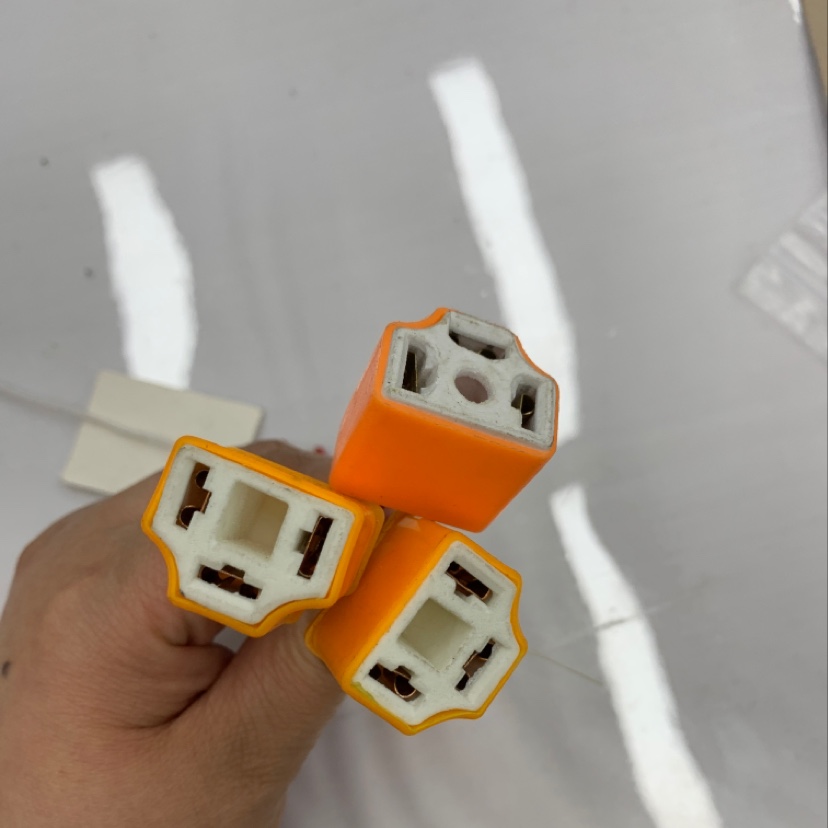

More Than Two Wires: The “Triad” Design Philosophy of the H4 Plug

At first glance, an H4 plug may look like any other connector. But beneath its compact shell lies a masterclass in functional engineering. Unlike simpler plugs, the H4 features a triple-contact system designed to manage two separate filaments within a single bulb—one for low beam, one for high beam—plus a shared ground. Think of it as a traffic controller at a busy intersection, directing currents so they never collide. Each pin has a dedicated role: one powers the near field, another activates the long-range beam, while the third maintains a stable return path. This elegant separation prevents cross-talk, reduces resistance, and allows drivers to switch modes instantly—without delay or dimming.

The Unsung Hero in Heavy-Duty Applications

Beyond automotive lighting, the H4 plug thrives where reliability is non-negotiable. Farmers rely on them in tractors exposed to dust and vibration. Emergency responders use them in portable floodlights that must ignite under pressure. Older industrial fixtures still depend on H4 connectors because they resist loosening even during constant machine operation. Its robust brass contacts, combined with heat-resistant insulation, make it ideal for environments where moisture, temperature swings, and mechanical stress are daily challenges. In these settings, the H4 isn’t just convenient—it’s trusted.

Why Hold On to “Old-School” Tech in a Smart World?

In an era of integrated LED arrays and digital control modules, one might assume connectors like the H4 are obsolete. Yet their persistence speaks to a deeper truth: modularity matters. While some modern lights solder LEDs directly into circuits, making replacements costly and complex, systems using H4 plugs allow users to swap bulbs in minutes. There’s no need to dismantle entire housings or recalibrate drivers. Maintenance becomes accessible, not reserved for specialists. Innovation doesn’t always mean reinvention—sometimes, the smartest solution is preserving what already works.

The Cost of One Wrong Connection: A Cautionary Tale

Consider the case of a technician replacing a headlight assembly who accidentally reversed the ground connection on an H4 plug. Instead of completing the circuit safely, the miswired plug caused reverse current flow through auxiliary lighting systems. Result? Multiple fuses blown, dashboard warnings triggered, and hours of troubleshooting. This real-world example underscores how vital correct polarity and proper wire coding are. Red for power, black or brown for ground—the H4’s standardized layout exists for a reason. Respect it, and your system runs smoothly. Ignore it, and chaos follows.

Can the H4 Survive the Future? Adapting to New Energy Realities

Far from fading away, the H4 plug is evolving. Modern variants now feature waterproof silicone caps, silver-plated contacts for improved conductivity, and enhanced strain relief for flexible wiring. These upgrades make them viable even in solar-powered garden lights or recreational vehicle electrical networks, where weather resistance and longevity are paramount. Retrofit kits now let homeowners integrate classic H4-based fixtures into energy-efficient setups, blending legacy compatibility with green technology. The H4 isn’t resisting change—it’s adapting to it.

What Are You Really Choosing When You Pick an H4 Plug?

Selecting the right H4 plug goes beyond mere compatibility. It’s a decision shaped by material quality, durability standards, and long-term performance. High-purity copper contacts ensure minimal voltage loss, while thermoplastic housings withstand temperatures up to 105°C. Independent tests show premium models endure over 5,000 insertion cycles without degradation—far exceeding basic versions made with cheaper alloys. Ask yourself: do you want a component that merely fits, or one that performs flawlessly year after year? The answer shapes both safety and operational efficiency.

The Quiet Dignity of Engineering Excellence

The H4 plug may never win design awards. It won’t be featured in glossy tech magazines. But every time a headlight ignites instantly on a rainy night, or a warning light stays off thanks to a secure fit, that’s the H4 doing its job—quietly, consistently, perfectly. It represents something deeper than function: a commitment to precision, resilience, and thoughtful design. In a world obsessed with the new, the H4 reminds us that true progress honors the details others overlook. After all, greatness isn’t always loud. Sometimes, it’s just well-connected.