What Is an H4 Plug? A Complete Guide to Its Uses and Advantages

Imagine this: you're driving down a winding country road just after sunset. The sky fades from amber to deep indigo, and with a simple flick of your thumb, your headlights blaze to life—cutting through the darkness like twin beacons. That instant illumination isn’t magic; it’s engineering. And at the heart of that seamless glow lies a tiny yet mighty component: the H4 plug. Often unseen, rarely celebrated, it's the silent conductor orchestrating one of the most critical safety features in your vehicle.

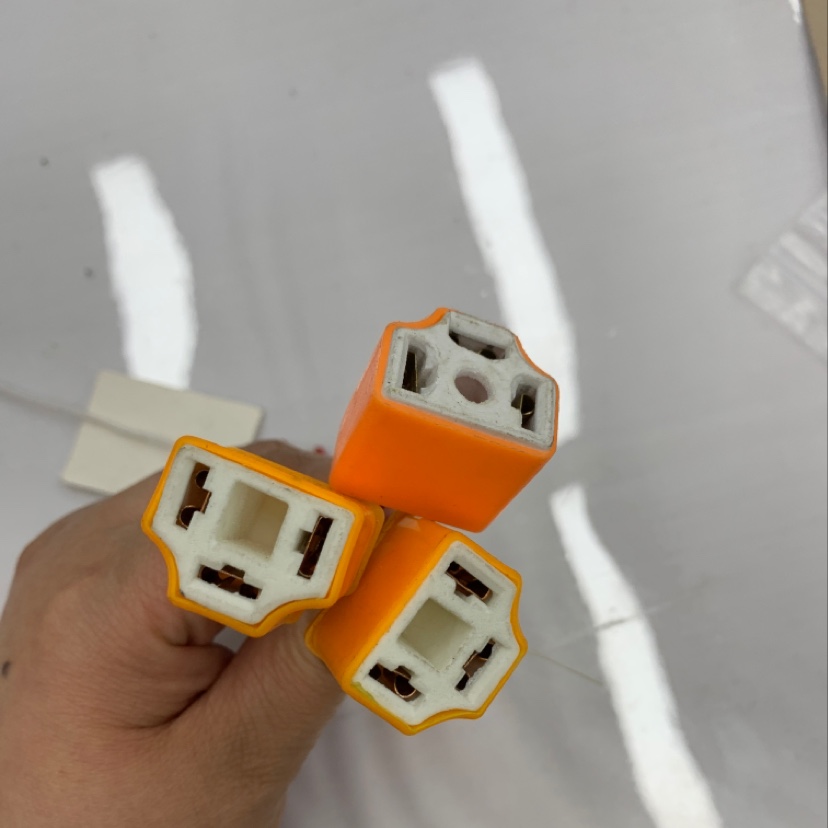

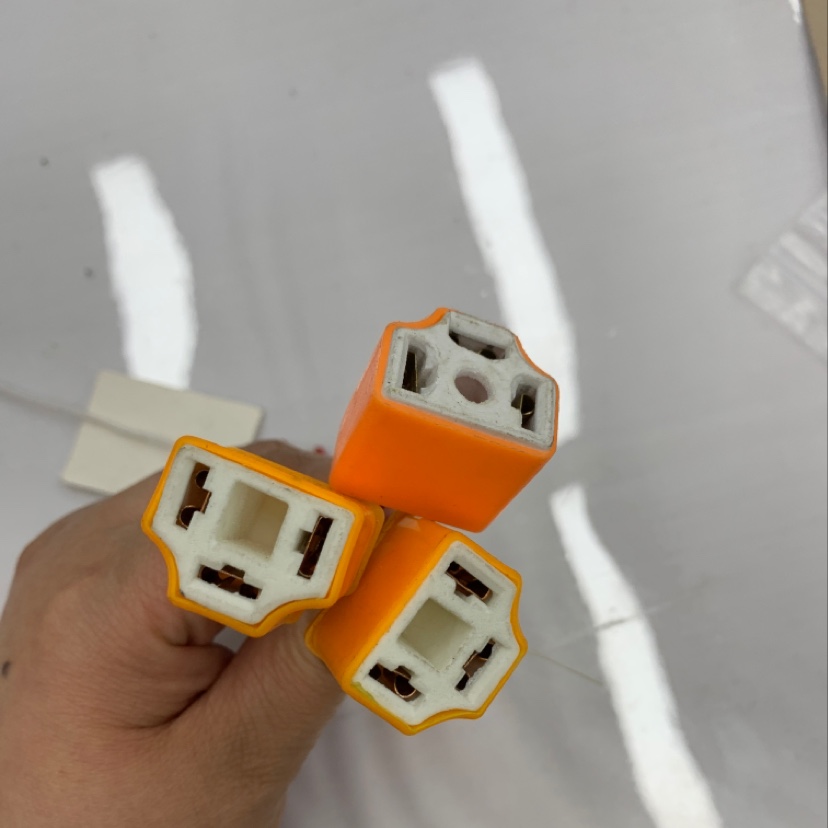

The H4 plug: small in size, massive in impact.

More Than Just Two Pins: The Technical DNA of the H4 Plug

Beneath its unassuming exterior, the H4 plug is a marvel of precision design. Unlike simpler connectors, it supports dual-filament bulbs, enabling a single bulb to handle both high and low beam functions—a crucial feature for responsive, adaptive lighting on the move. With three metal contacts (two for the filaments and one ground), the H4 ensures clean power delivery under fluctuating loads. Think of it as the neural synapse of your headlight system: receiving signals from the switch, translating them into action, and delivering consistent brightness without hesitation.

Constructed from heat-resistant materials like PBT plastic and brass contacts plated with tin or silver, the H4 plug maintains integrity even in extreme engine bay temperatures. Its standardized pin configuration—spaced exactly 90 degrees apart—ensures foolproof alignment, reducing wear and preventing short circuits. This isn't just connectivity; it's reliability engineered down to the millimeter.

From Motorcycles to Massive Warehouses: Where H4 Plugs Shine

You’ll find H4 plugs far beyond passenger cars. On sport bikes where space is scarce, their compact form allows efficient routing and secure connections despite constant vibration. In industrial settings, high-bay warehouse lights powered by H4-compatible halogen or HID lamps rely on these plugs for stable, long-term operation under continuous use. Even specialized machinery—like agricultural tractors working through muddy fields or emergency response vehicles racing through rough terrain—trust H4 connectors for their ruggedness and fail-safe performance.

What makes the H4 so adaptable? Universal compatibility. Whether embedded in a vintage muscle car or integrated into modern off-road equipment, the H4 interface remains consistent. This cross-industry acceptance has cemented its status not just as a part, but as a platform.

Why Engineers Keep Coming Back to the H4

If innovation means replacing the old with the new, then the enduring presence of the H4 plug is a testament to its unmatched practicality. Engineers favor it for several compelling reasons: exceptionally low contact resistance minimizes energy loss and heat buildup, while the robust housing resists corrosion and mechanical stress. The bayonet-style locking mechanism ensures a snug fit that won’t loosen over time—even on bumpy roads.

Compare this to some quick-connect alternatives that degrade under sustained load or fail during moisture exposure, and the H4’s superiority becomes clear. It’s not flashy, but in environments where failure isn’t an option, dependability speaks louder than novelty.

How the H4 Became a Global Standard

The story of the H4 begins in the 1970s, when automakers sought a unified solution for dual-beam headlights. The International Electrotechnical Commission (IEC) stepped in, standardizing the H4 as part of the IEC 60809 specification. This move transformed it into a global language of light—one understood by manufacturers from Germany to Japan, Brazil to India.

Because of this widespread adoption, sourcing H4 plugs and compatible bulbs is easier and more cost-effective than ever. Instead of reinventing the wheel with proprietary systems, companies continue using H4 technology because it works—proven, predictable, and supported by decades of real-world data.

Will Smart Lighting Make the H4 Obsolete?

With LEDs and digital lighting controls on the rise, some wonder if traditional H4 plugs are living on borrowed time. While full LED assemblies often bypass H4 connectors entirely, there’s still a thriving market for hybrid solutions—especially in retrofit kits and mid-tier vehicles. Here, the H4 acts as a bridge between legacy wiring and upgraded lighting tech.

Moreover, in regions where affordability and serviceability matter most, the H4 remains indispensable. Replacing a burned-out bulb takes minutes and costs little—something not always true with sealed LED units. So no, the H4 isn’t disappearing. It’s evolving, quietly supporting the transition toward smarter lighting while remaining accessible to all.

Pro Tips for Handling H4 Plugs

If you’re replacing an H4 plug or bulb, listen to the old-timer advice: always disconnect the battery first. Handle the connector gently—bent pins can ruin conductivity. Make sure the tabs align properly before twisting into place, and never touch the glass of halogen bulbs with bare fingers; oils can create hot spots and shorten lifespan. Finally, inspect the socket for signs of melting or discoloration—a clue that underlying wiring may need attention.

These small steps preserve performance and prevent premature failures. After all, even the toughest components depend on proper care.

Every Beam of Light Has Its Silent Guardian

So next time your headlights ignite the night, take a moment to appreciate the unsung hero behind the beam. The H4 plug doesn’t seek applause. It doesn’t need recognition. But without it, that confident sweep of light across the asphalt simply wouldn’t exist. Like a stagehand in a theater production, it operates in the shadows—ensuring every performance goes flawlessly. In a world chasing the next big breakthrough, sometimes the greatest wisdom lies in honoring the fundamentals. And the H4 plug? It’s engineering excellence in its purest, most enduring form.