Why H4 Plug

Among the many types of automotive light bulb plugs, why more and more professional technicians and car owners prefer the H4 plug? The reason behind this is not only its wide applicability, but also its ability to maintain excellent performance under extreme conditions. As a classic dual-core socket design, H4 plug is widely used in various brands of cars around the world. It can not only meet the basic functional requirements, but also become one of the most popular products on the market because of its high compatibility and durability.

Stable and reliable power transmission

It is important for any driver to ensure that the lights are working properly. The H4 plug is known for its excellent electrical conductivity and very low resistance, which effectively reduces energy loss and prevents voltage fluctuations. This means that even in the face of bad weather or complicated road conditions, your headlights are always as bright as new, providing a clear view while improving the safety factor of driving at night. Whether it is a highway or a rough road, having an efficient power transmission system is a key factor in ensuring the safety of drivers and other road users.

Applicable to all types of vehicles

Whether it is imported luxury cars or domestic economy cars, almost all mainstream brands are using the same specifications of the H4 lamp holder interface. This universal design makes the replacement of lamps simple and fast and low cost. More importantly, due to the use of standardized production processes and technical specifications, each factory-qualified product has undergone strict testing and certification procedures, thereby ensuring the consistency and reliability of product quality. No matter what model you drive, choosing the right H4 plug means choosing the possibility of easy maintenance and support for future upgrades.

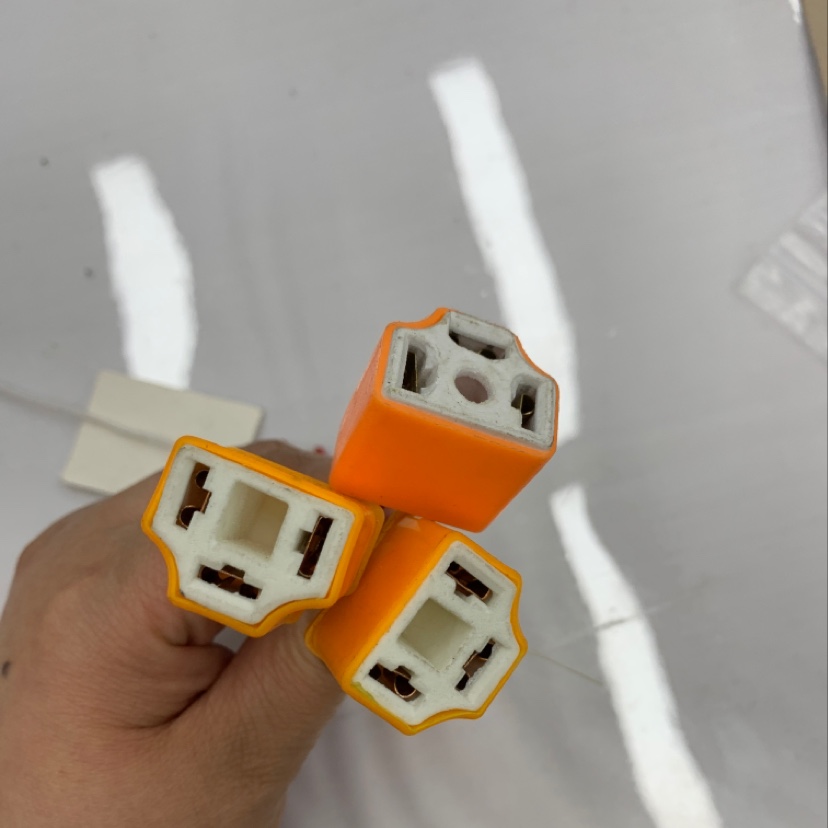

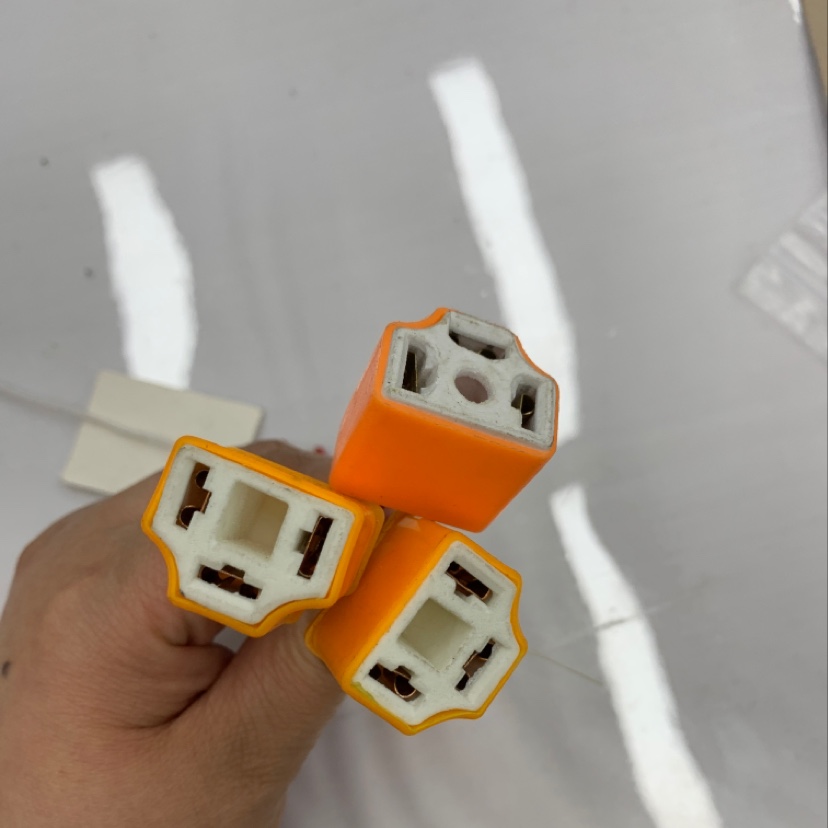

Durable Materials and Craftsmanship

A small H4 plug seems inconspicuous, but the internal structure is very exquisite. It is composed of high-strength metal shell, high-temperature insulator and gold-plated contacts. All parts are made of the most high quality raw materials for processing. Coupled with the application of advanced automated production lines with precision mold stamping technology, each finished product can withstand long-term vibration shock without deformation and loosening, and is truly durable. Manufacturers are constantly seeking to innovate and strive to reduce costs without sacrificing functionality, so that more consumers can benefit from the convenience and services brought by this advanced technology.

Excellent contact performance and anti-vibration ability

Good electrical contact is one of the prerequisites for efficient and stable current flow. To this end, manufacturers continue to improve the design of H4 plugs, adding a spring sheet structure to enhance the clamping force on the traditional basis, and using a special coating treatment to increase the surface friction, thus significantly improving the plug feel and stability. At the same time, reinforcement measures are taken for the parts prone to failure, such as strengthening the strength of the fixed screw position, so that it is not easy to fall off and damage. The optimization of these details not only enhances the service life of the product, but also provides users with a more convenient operation experience.

Guide to correct installation method

Although the H4 plug has many advantages, if it cannot be operated according to the standard process, it may cause adverse consequences. In order to avoid this situation, a complete set of assembly instructions will be described in detail, including the preparation steps (disconnect the power supply), the specific implementation process (clean the socket hole) to the final inspection and confirmation link (test light brightness). By following these tips, even friends who are trying to do it themselves for the first time can successfully complete the task and enjoy the joy of success. Proper installation and maintenance can not only extend the service life of equipment, but also help prevent potential risks and escort daily travel.