Breaking the industry standard | How can H4 plug become the benchmark of power connection in heavy industry?

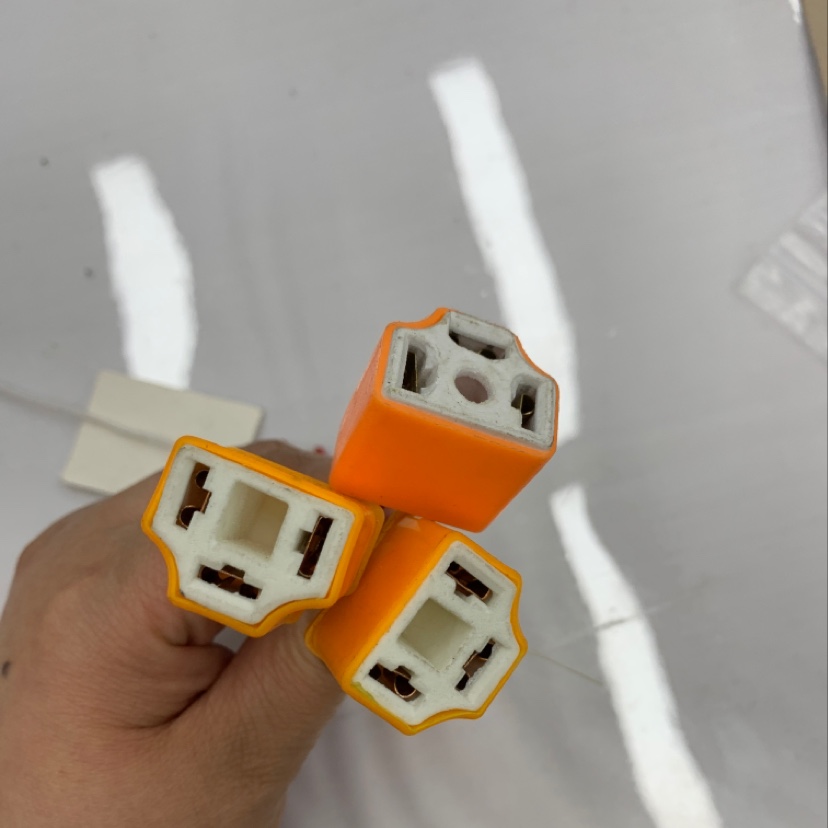

With its precision manufacturing process and high-performance design concept, the H4 plug has established a new power connection specification in many high-intensity operating environments such as construction machinery, large household appliances and special vehicles. Compared with the regular interface scheme, it can continue to operate stably under extreme conditions, greatly reducing the risk of failure caused by poor contact. This is not only a test of product quality, but also an important link that cannot be ignored in the process of promoting industrial upgrading.

The scientific and technological power behind the conductive performance | Reveal the efficient power transmission principle of H4 plug

The core components of the plug are made of high-purity copper, combined with special anti-oxidation coating treatment, making the current transmission process more smooth and stable. Even in the face of complex conditions such as frequent start-stop or load fluctuations, it can achieve millisecond response and zero-delay conduction performance, providing a strong energy support system for all kinds of professional equipment. Such technological innovation allows every minute of electricity to be fully utilized and reduces unnecessary energy consumption and waste.

Extraordinary durability under rigorous testing | Interpreting the key factors for extending the service life of H4 plugs

In order to cope with the challenges of high-frequency plugging and harsh environment, the manufacturer has carried out tens of thousands of wear-resistant tests and a number of limit conditions. The results show that under normal maintenance conditions, it can serve continuously for many years without obvious signs of aging, which is significantly better than the average level of mainstream competitors in the market, and saves a lot of later operation and maintenance costs for enterprises. This product quality that can stand the test of time is the core component characteristics that modern industrial production urgently needs.

All-round security system | Why is the H4 plug a reliable electrical accessory?

From the anti-accidental touch locking device to the overload protection module, every detail reflects the people-oriented safety concept. Especially in the high temperature and humid or dusty environment can still maintain a good insulation effect, effectively prevent the frequency of leakage accidents, and comprehensively protect the personal safety of staff and property from loss. As a qualified industrial product, safety is always the first consideration, and this is perfectly reflected in the H4 plug.

Matching multiple application scenarios | Flexible expansion of your industrial equipment supporting solutions

whether it is the heavy mining machinery used in the construction site, or the intelligent control system on the factory automation assembly line, or the mobile generator set or even the new energy commercial vehicle platform, we can find the configuration version of the technical parameters that perfectly fit it. This high degree of compatibility has made it one of the most important and indispensable components in many fields. Its existence is not only a simple physical connection means, but also a powerful driving force to help enterprises build intelligent and standardized operation architecture.